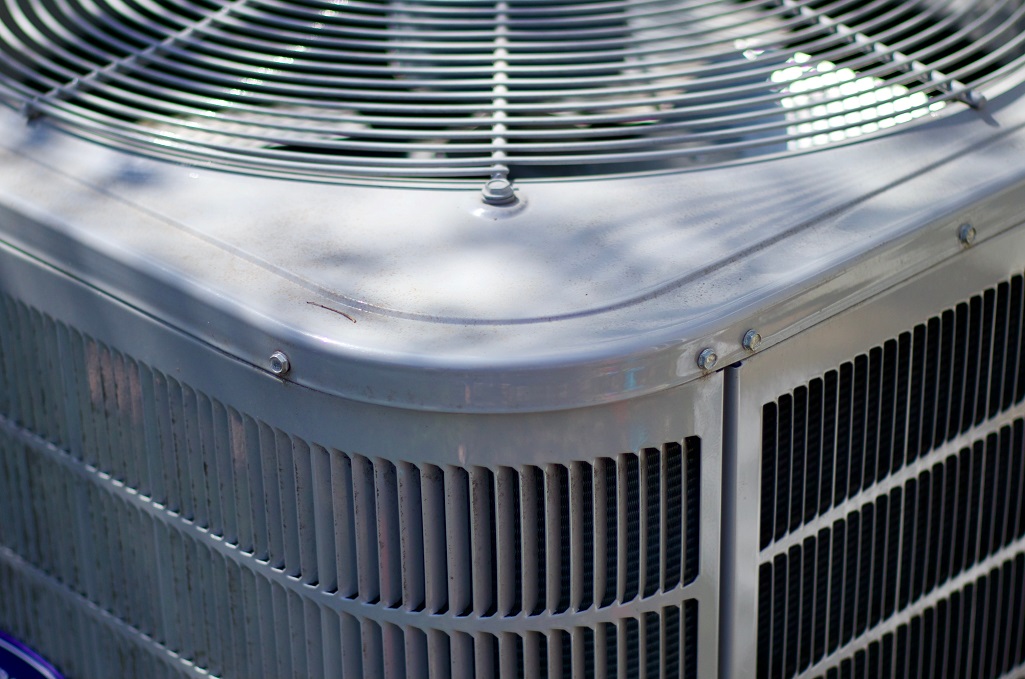

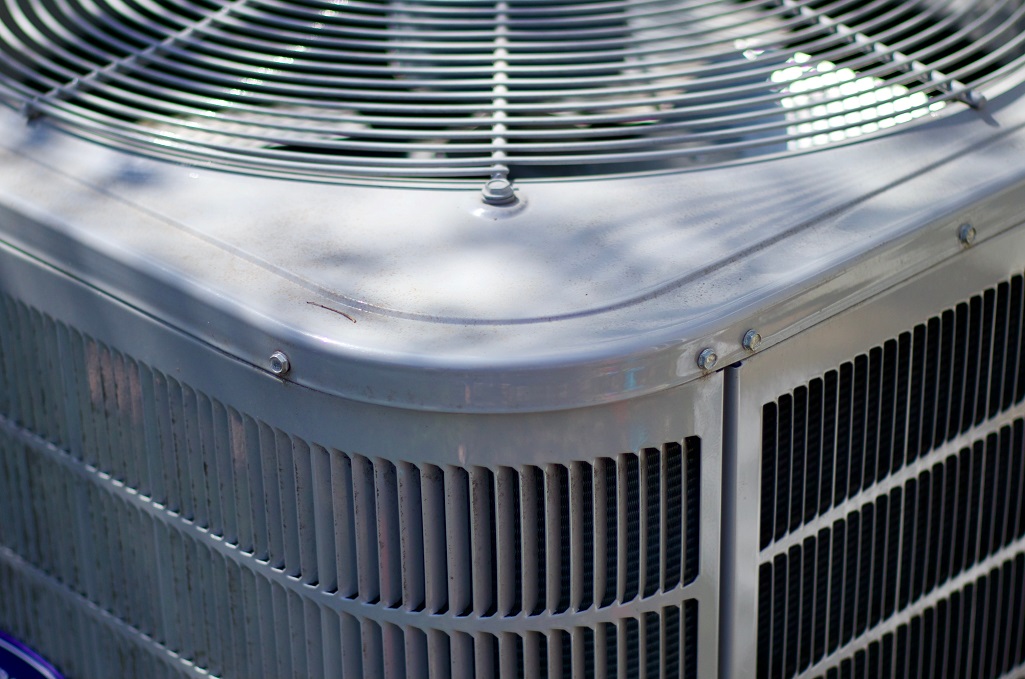

Best rated Heating and Cooling Guide HVAC system for beginner

Control rooms, Switchgear Halls Electronic Equipment Rooms, and Battery Rooms in a petrochemical facility need the use of HVAC systems.

Trying to achieve an ACM Panel look in your house or new build home?

One of the major attractions of stucco is its incredible versatility. As a material that can be finished in an endless array of colors, textures and shapes, many architects have leveraged these qualities to create unique and stunning buildings.

Terms and conditions apply…

At this point, you will research an article that will add value to our readers.

Next, create your content, keyword-focused and SEO-friendly and you may include up to 2 links relevant to the content.

Submit it to our Editors department where we will be looking out for Value in general.

We will review it and upon approval, we will publish it or schedule it accordingly.

WHAT ARE ACM PANELS

Traditionally, steel and wood frames have been the most popular materials used in building construction, but recent years have seen a growing surge in popularity for factory-engineered aluminum composite materials. These durable, versatile materials have a variety of uses and come in a number of different shapes and thicknesses, however, the manufacturing process is the same in every case. Two large, thin aluminum sheets are bonded together using a non-metal core, usually plastic polyethylene (PE) or thermoplastic mineral-filled core (FR). A fire retardant core (FR) is a panel that has a fire retardant adhesive bounded by two thin sheets of aluminum. FR core composite panels also offer similar benefits to PE core composite panels. The exception is that FR core panels offer compliance with many fire codes worldwide.

After the bonding is completed, the panel is finished using either a metallic or PVDF paint. The resulting panel looks somewhat like a sandwich, hence the alternative name aluminum sandwich panels.

While the technology to create these composite materials has been around since the ’60s, recent requirements for sleek, cost-effective architecture has really increased the use of ACM’s for cladding, insulation and signage in buildings.

DIBOND® — A longtime industry standard, DIBOND® comprises two pre-painted aluminum sheets (0.012 in thick each) sandwiching a solid polyethylene core. It is the flattest panel on the market, approximately one-half the weight of a solid aluminum sheet, durable for outdoor applications, and well suited for digital and screen-printed graphics. It can be routed and returned to add dimension, or roll-formed to create sweeping curves. Fabrication options also include cold mounting graphics, repositioning vinyl, painting, saw cutting, routing, and die cutting/punching. DIBOND® aluminum panel will not bow or experience “oil can” wrinkling.

DIBOND® is also available with a specialty mirror finish offering outstanding reflective properties similar to those of a conventional glass mirror, without the breakability of glass and at about half the weight. The mirror surfaces can be both screen and digitally printed as well as a laser engraved.

DIBOND® exhibits long-term application life in exhibits and kiosks; standard or archival framing; and interior, exterior, and structural signage.

Fire rating: DIBOND® is Underwriters Laboratories® Inc. recognized for UL 94V-0 and is a UL-recognized component for electrical signage. All thicknesses meet the criteria for ASTM E-84 and are Class 1 or Class A materials.

E-PANEL™ — The aluminum facers in the E-PANEL™ material are slightly thinner, at 0.008 in, than those in DIBOND®. It is recommended for flat-panel applications only. It is suitable for cold mounting graphics, repositioning vinyl, both digital and screen printing, and painting. It can be saw cut, routed, or die cut/punched.

Sky Stucco Systems, serves clients in the Greater Toronto Area including North York, Etobicoke, Scarborough, Woodbridge, Mississauga, Brampton, Vaughan, Richmond Hill, Thornhill, Oshawa, Whitby, Newmarket, Burlington, Milton, Oakville, Aurora, Woodbridge, Orangeville, and Caledon

Do you want to keep up to date about Stucco news and application? We are against spamming so dont you worry!!!

Sky Stucco Systems.

Copyright © 2025. All rights reserved.

Control rooms, Switchgear Halls Electronic Equipment Rooms, and Battery Rooms in a petrochemical facility need the use of HVAC systems.

Exterior Insulated Finish System installation near Bradford, On 2019. A

When I work with clients as just a certified life coach, I urge them to make their living spaces more organized, personal, and roomy. The vast majority of my customers live in apartments, generally in urban settings, and there is often a significant difficulty with regard to size, layout, and the ability to ensure that all apparel, accessories, and shoes (don’t forget shoes!) fit properly in the space.

If you’re dealing with a leaky basement, you’re not alone.

When you’re installing a non-metallic electrical cable, you must identify the sections of the cable: the outside sheath (the jacket) and the interior conductors. What seems to be colored “wire” is really a sheath that covers the copper wires within.

Upgrades with stucco make an old house look new again. Stucco has been in use since ancient times. Modern homes often have a stucco facade instead of solid stucco walls. Whether solid or facade, time and weather could cause cracking and fading. Instead of replacing the stucco, use a few steps to upgrade it while increasing the value of your property and reduce maintenance costs.

The tips and tricks in this article are perfect for

Grime, mold, and other unattractive things can accumulate on your